Allan is the purchasing manager from New Zealand medical products company, he was very eager when he first spoke to us.

they are going to the USA for exhibition in 1 week, but their exhibiting equipment is not working properly due to the lack of some important CNC machining parts and now they need these important CNC machining parts very urgent, their local CNC machining factories are not able to do these urgent tasks in 1 week.

Allan said They have 2 CNC machining suppliers in China, Before that, one of their Chinese CNC machining suppliers had already supplied them with the CNC machining parts, but the dimensions did not meet their requirements, which cause the equipment doesn’t work well, but the equipment is the most important thing in this exhibition, and for which the whole team had been preparing for 6 months.

Now their supplier is not able to manufacture these CNC machining parts again because they are on full load, So now Allan wants to get fast delivery services on CNC machining services from PTS

Against the time, we successfully make 37 customized parts in 24 hours.

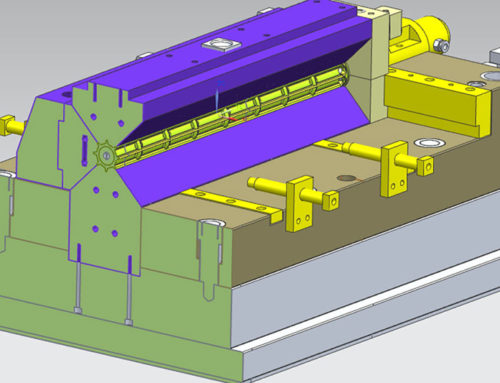

First Hour: Review drawings, and communicate with the customer on the technical details of the drawing requirements, there are some tolerances +/-0.005mm, need to use the precision grinding machine to process, but it will take much time with the precision grinding machine to ensure the tolerance within +/-0.005mm, We had a great challenge.

Second Hour: make the CNC program and start ordering the material. Normally we order the material today, it will get in our factory on the next working day, but this time it was very urgent, our purchasing staff drove to the supplier’s factory and pulled the material straight back to the factory.

Third Hour:

The material gets into our factory, and our IQC will measure the material hardness and record it.

Fourth Hour:

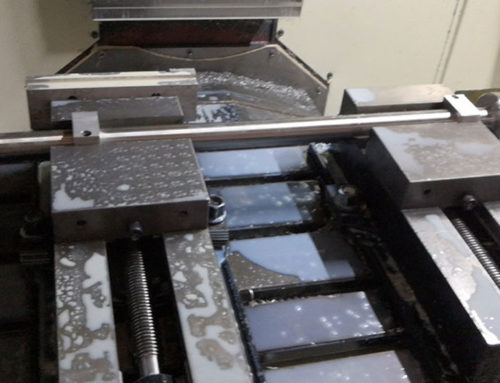

The material is ready to machine, the CNC program is done, Now the material is processed according to the pre-defined CNC program,

Nineteenth Hour: CNC turning working is done, the next step is CNC milling.

Twenty-third hour:

CNC milling working is done, the next step is precision grinding.

Twenty-sixth hour:

Precision grinding working is done, the next step is inspection for full dimensions.

Thirtieth hour, inspection for full dimensions is done, send FAI report to customers, and ship parts.