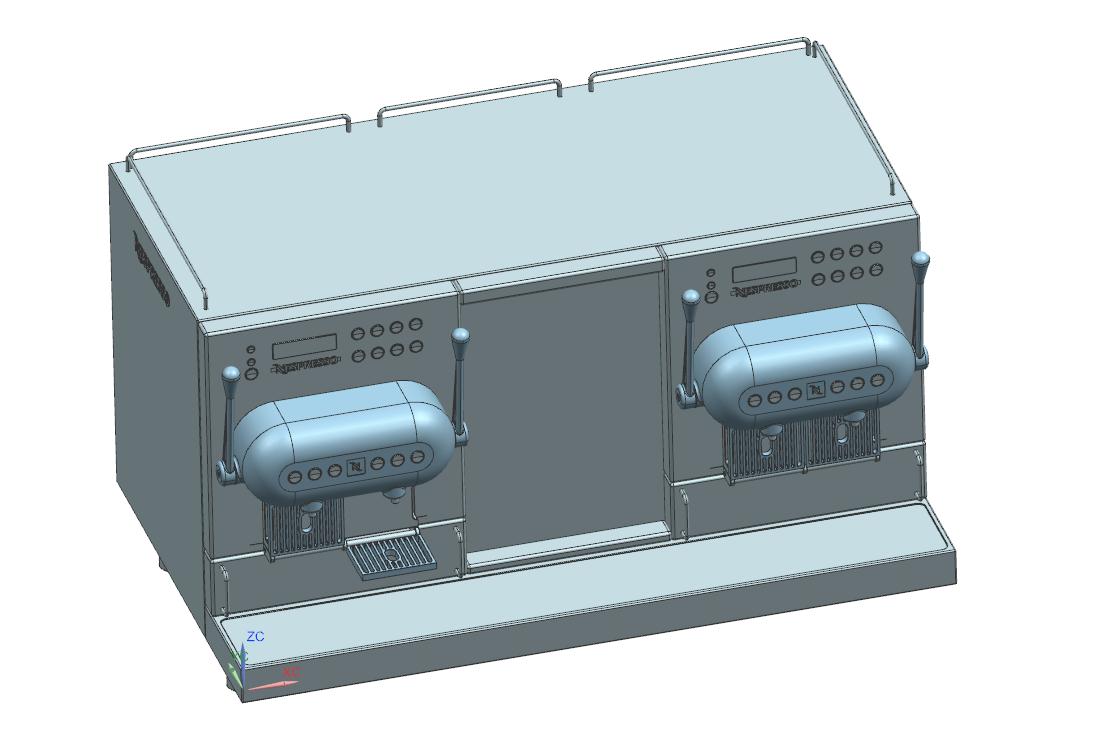

Alex found us on Google, they are a new Australian startup that main business is a coffee maker.

Alex wanted to get a solution from us on cost-down, recently their company considered redesigning the new coffee maker to suit the market, but the ultimate goal was to reduce the costs, as Alex said, these new parts as a gift to potential customers, they hope to reduce the cost by min. 20% of the new 2000 sets products.

After talking to Alex, we knew they are currently working with a factory in China, BUT the supplier has increased their prices by 15% to instead of helping them lower their prices, which makes Alex very unhappy, so it’s very important to work with a supplier that is consistent in quality and price, but our guess is that Alex will be looking for more than just one factory, he will be looking for multiple suppliers to compare.

At the end of the project, Alex told us that he had talked with 8 suppliers and chose us because of our company’s reputation and ability to produce the products he needed, as well as to optimize their design and reduce costs.

From 45 to 27 parts.

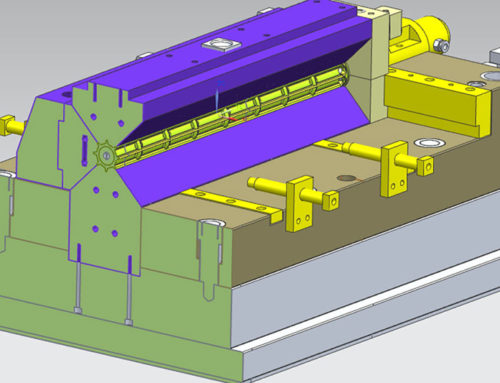

The project was handled by our project manager, Jack, who pointed that the customer’s current product design are with 45 different parts on CNC machined parts, many of which were machined or purchased separately, with the most costly part being the housing, box. Jack wanted to simplify the product structure and reduce costs by combining multiple parts and eliminating many individual parts, as designed, the new structure would only require 27 parts on CNC machined parts.

Redesign and material selection to address challenges

Our project manager Jack worked with Alex’s engineers together to redesign the structure of the coffee maker, based on our DFM analysis, resubmitted more rational 3D drawings of the redesign, which were risk-free and met Alex’s requirements, and would have significantly reduced processing time and costs.

Alex with Their mechanical engineers visits us.

One of the important decisions Alex and his team had to make was to re-select the materials for the parts. We sent out some samples to help Alex’s team choose the feeling, finish, and color to reduce the cost of the material.

In the end, Alex ordered 2,000 unit parts he needed from us, and we helped Alex reduce their costs by 57.5%, making them much more competitive in the market.