Polypropylene (PP) Injection Molding Factory / Manufacturer

Free & Fast DFM Feedback

No Minimum Order Quantities

T1 Samples As Fast As 10 Days

- 24/7/365 Operation Support

Supplier of Stanford AI Lab / TESLA

Machines Ranging From 30 Tons to 1,600 Tons

Professional on Polypropylene (PP) Injection Molding to meet your rapid prototypes and production needs

Relied on by :

Our Polypropylene (PP) Injection Molding experience & Applications

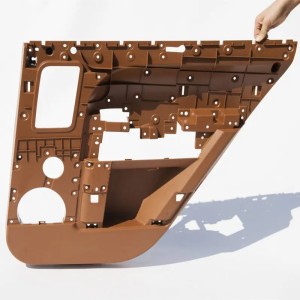

Polypropylene (PP) has a wide range of applications. It can make heat-resistant parts around automobile engines, medical machinery, and tableware that must be sterilized by boiling, high pressure, etc. It can also be used to make axle treads of automobiles that need to resist bending fatigue, covers, and flaps of documents and various containers, etc.

Polypropylene (PP) is widely used to make chemical pipes, various storage tanks, and filter press frames. It can also produce strong products and pipes such as fiber, monofilament, flat wire, flat strip, rope, etc. Flat wire can be made into woven bags. In addition, PP can also be made into various films to be used as packaging materials, etc.

Aerospace

Automotive

Consumer Electronics

Defense

Dental

Chair

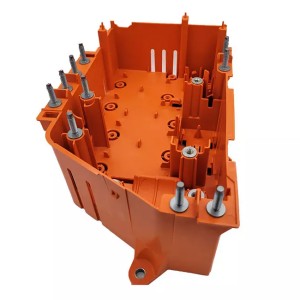

Electrical Equipment Supplies

Electronics Electrical

Farming

Furniture

Home appliances

Home Garden

Machinery

Marine

Container

Medical

Packaging

Pharmaceutical

Safety

Sports

Our Polypropylene (PP) Injection Molding Processes

We supply one-stop Polypropylene (PP) Injection Molding service from product design, mold manufacturing to injection molding and product assembly.

Request Instant Quote

Our dedicated engineers will provide a response within 8 hours, ensuring the process goes on smoothly.

Polypropylene DFM analysis

Comprehensive analysis product manufacturability and optimization recommendations for your design.

Polypropylene Mold Flow Analysis

Use CAE technology to simulate the real Injection molding process before Injection mold making.

Polypropylene Molds Design

Our Molds Last 50% Longer Than Other Molds, They Can Run Up To 15-20 Years In Most Cases.

Polypropylene Molds Making

We have our own mold making factory,This will ensure the mold quality of all manufacturing processes. The mold property is yours.

T1 Polypropylene Sample Inspection

Few or A dozen samples should be produced for assembly/functional testing before mass production.

On-Demand Polypropylene Molding

After the trial Polypropylene molding phase, we start batch molding, which uses powerful machining to manufacture parts at fast rates to save on time and costs.

Strict Inspection Delivery

We follow international tolerance standards to ensure our parts meet your requirements, and We have the ability to deliver products anywhere in the world that you specify.

OUR HAPPY CLIENTS

You’ll work with good value Polypropylene (PP) Injection Molding Factory Manufacturer / Supplier just like them…

Customers

Worry about our quality? See what our happy customers said about our products/services.

You will LIKE us once you started with us!

“PTS always can quickly find a solution for any complex Manufacturing situation. With their capacity, quality, and knowledge, PTS can help any company achieve its goals.”

“In manufacturing, reliability is everything. That’s what we get from PTS industrial Ltd and they have also reduced our rejects by up to 90%. If all our equipment worked as well…our jobs would be easier, and our customers would be very happy”

“We started using engineering parts around 10 years ago from PTS. We have always received excellent parts from every batch, timely replies to all our queries, and very competitive quotes and make us more competitive in the market.”

OEM Polypropylene (PP) Injection Molding Company—Get Instant Quote Now !

No Matter Where You Are, We’ll Turn Your Idea & Design To Reality.

PTS is your China partner, your China researching and developing team, your easteel and south of China Polypropylene (PP) Injection Molding manufacturer / Services.

Polypropylene (PP) Injection Molding Definitive Guide (2023)

Table of Content

1. What Is Polypropylene(PP)?

Polypropylene, abbreviated as PP, has a chemical structure of (C3H6)n and is a thermoplastic resin made by the polymerization of propylene. It is a white waxy material, transparent and light in appearance, with a density of 0.89~0.91g/cm3, flammable, melting point 189℃, softening at 155℃, uses temperature range -30~140℃.

It can resist the corrosion of acid, alkali, salt liquid and a variety of organic solvents below 80℃ and can be decomposed under high temperatures and oxidation.

Polypropylene(PP) is a high molecular weight propylene polymer, introduced late and was not put into industrial production until 1957. Due to the abundance of raw materials, the waste gas of high-temperature oil cracking contains a large amount of propylene, which is collected and blunted as a major initiative to turn waste into treasure.

Polypropylene(PP) is a thermoplastic synthetic resin with excellent performance. It is a colorless and translucent thermoplastic light weight general purpose plastic with chemical resistance, heat resistance, electrical insulation, high strength mechanical properties and good high wear resistance processing properties, etc. It is widely used in the production of garments, blankets and other fiber products, medical devices, automobiles, bicycles, parts, transport pipes, chemical containers, etc. It is also used in food and pharmaceutical packaging.

2. Common Properties of Polypropylene (PP)

Polypropylene (PP) has the lowest density of 0.90-0.9lg/cm3 compared with other general thermoplastics, and has excellent mechanical properties such as tensile strength, compressive strength, surface hardness and modulus of elasticity, as well as outstanding stress cracking resistance and wear resistance.

Polypropylene (PP) has good heat resistance, does not deform even when heated to 150 ° C in an environment without external force, can be steamed in boiling water, and can be used stably for a long time at 100 ° C or more.

Polypropylene (PP) almost does not absorb water, and has excellent chemical stability, except for fuming sulfuric acid and strong oxidizer. It is stable to the rest of the medium, it has excellent high-frequency electrical properties, and is not affected by humidity, easy to shape and process, available for injection moulding, extrusion and hollow molding and other methods to shape a variety of products.

Polypropylene (PP) is non-toxic and tasteless, especially valuable is that Polypropylene (PP) has excellent resistance to bending, can be repeatedly folded without damage, which is difficult to do with any other plastic.

However, Polypropylene (PP) has poor cold resistance, bad weather resistance, insufficient high temperature rigidity, and is easy to burn in case of fire. In order to extend the service life and expand the application range, Polypropylene (PP) plastic can be modified to overcome the weaknesses and strengthen the advantages.

3. What Are The Best Polypropylene (PP) Injection Molding Parameters?

3.1 Polypropylene (PP) Injection Molding Guidelines

3.1.1) The hygroscopicity of Polypropylene (PP) is very small, so it does not need to be dried before polypropylene injection moulding, but should be dried if the humidity exceeds the allowed value.

3.1.2) The Polypropylene (PP) structure contains tertiary carbon atoms, so the antioxidant capacity is very low, and antioxidants should be added during polypropylene injection molding.

3.1.3) The molten material should be avoided to stay in the barrel for a long time during polypropylene injection molding. Polypropylene (PP) will degrade thermally when it exceeds 280 °C Celsius, so the performance will be deteriorated.

3.1.4) Polypropylene (PP) melt fluidity is good, between HDPE and LDPE, the melt flow rate is 2-9g/10min. Melt viscosity decreases with the increase of injection pressure and temperature, Easy to mold thin-walled, large plastic parts.

3.1.5) Polypropylene (PP) is crystalline and has a wide range of molding shrinkage, from 1.0% to 3.0%, and has a more obvious post-shrinkage, so it is easy to get defects, such as sink marks, dents and deformation with strong directionality.

3.1.6) The melting point and melt heat content of Polypropylene (PP) are higher than LDPE, and more heat will be released in the process of crystallization and cooling, so the mould should have a better cooling system to reduce the deformation of plastic parts.

3.1.7) Due to the thermal shrinkage and crystallization of Polypropylene (PP), the specific volume in the pp injection molding process has a large change, and defects such as bubbles and dents are easily produced in the tendons, holes and parts with large wall thickness.

3.1.8) The orientation is obvious when the melt temperature is low, especially at low temperature and high pressure, so the molding temperature should be controlled during polypropylene injection molding .

3.1.9) The shrinkage of Polypropylene (PP) plastic parts is large when demoulding, it should be placed on the shaping device for more than one day after demoulding to fix the shape, and for the plastic parts with high dimensional accuracy, heat treatment can be carried out in time.

3.1.10) Due to the large shrinkage rate of polypropylene injection molding, low temperature is brittle, so the wall thickness of the plastic parts should be uniform, avoid notches, and sharp corners to prevent stress concentration.

3.1.11) If the holding time is too long, there will be a large shrinkage of the plastic parts and quality defects; implement scientific injection molding to determine a reasonable holding time.

3.2 Polypropylene (PP) Injection Molding Main Parameters & Processes

3.2.1) Injection machine type selection:

Polypropylene injection molding can be done by screw injection machine or plunger injection machine, and the former is generally used more often.

3.2.2) The moisture content of the injection material should not exceed 0.05%, otherwise it should be dried at 80~l00°C for 3~4Hours before polypropylene injection molding .

3.2.3) Barrel temperature:

A lower barrel temperature can be selected when the injection pressure and speed are low.

The melting point and decomposition temperature of polypropylene are higher than polyethylene, with good thermal stability, the melting point temperature range is 165-170°C, and the decomposition temperature is higher than 350°C. The molding temperature range is wide, generally 205-315°C.

General barrel temperature control at 210-280°C, nozzle temperature is 10-30°C lower than the barrel temperature. when molding thin-walled, complex products, the material temperature can be increased to 280-300°C; production of thick-walled products, the barrel temperature should be reduced to 200-230°C, to prevent the material in the barrel for too long time and cause thermal degradation.

However, the barrel temperature should not be too low, otherwise the macromolecular orientation will increase and the products will be easily warped and deformed.

3.2.4) Mold temperature:

Mould temperature should be determined according to the thickness and performance requirements of the product, usually adjusted at 20-60°C, which is not only conducive to crystallization, but also conducive to the relaxation of macromolecules, thus reducing

molecular orientation and reduce internal stress.

When the mold temperature is lower than 20°C, the plastic parts are not smooth, easily produce welding lines, and welding marks, and above 90°C, easy to warp and deformation.

3.2.5) Injection Pressure

In Polypropylene injection molding, increasing the injection pressure helps to increase the fluidity of the melt. The injection pressure of plunger injection molding machine is higher than screw type.

Generally, it is controlled at 70-100MPa, and the specific value is determined during mold testing, so that the plastic parts do not short-shot, overflow and do not have dents and bubbles or any others defects.

3.2.6) Due to the large shrinkage rate of polypropylene, post-shrinkage often occurs when the product is stored at room temperature.

90% of the total post-shrinkage is completed within 6 hours after the product is removed from the mould, and the remaining 10% occurs within the next 10 days, so the product should be stored on the shaping device for 1 day after it is removed from the mold.

For products with the complex shape or high dimensional stability requirements, heat treatment should be carried out, that is, the products are placed in hot air at 150°C, heat treatment 0.5~1Hours. When the wall thickness of the products is greater than 3mm, the time can be extended appropriately.

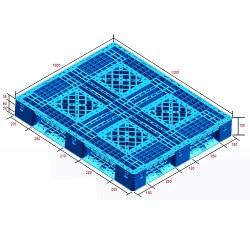

4. Polypropylene bin & containers application features and applications

4.1) Polypropylene Bin & Containers is a plastic product made of copolymer polypropylene as the main raw material. Like other polypropylene plastic products, polypropylene Bin & Containers has bright color, are beautiful, high strength, light weight, long service life, insect-proof, moisture-proof, mold-proof, non-toxic, clean and sanitary, easy to clean and convenient to handle.

4.2) The structure of the container is divided into two types: complete type and folded type: complete type containers are injected in a larger injection machine (injection volume greater than 1000cm³ or more); folded type containers are assembled from multiple parts, each part is injected in different sizes injection machines and then assembled together.

4.3) The container application is mainly used for the turnover and transportation of various food, beverage, agricultural products, industrial parts, chemical products, pharmaceuticals, etc. The transfer packaging box is convenient for crating, storing, handling, and storing various items.

5. What to pay attention to polypropylene Bin & Containers injection molding

5.1) Raw Material Selection

Polypropylene container injection molding raw materials, mainly is copolymer polypropylene resin, the requirements of the resin melt flow rate (MFR) in the range of 1. 5 -5g/10min, notched impact strength greater than 10kg/m2, tensile strength greater than 23MPa, Rockwell hardness greater than 75.

In order to reduce the production cost of the product, about 10% of random polypropylene filler masterbatch can be added to the main raw material. If the product needs to have color, some color master batch must be added to the resin.

5.2) Barrel Temperature

Polypropylene bin injection molding process parameters (for reference only), barrel temperature:

Front Temperature 190 ~ 220°C,

Middle Temperature 220 ~ 240°C,

Rear Temperature 180 – 200°C,

Nozzle Temperature 170 ~ 200°C.

5.3) Injection Pressure And Molding Cycle Time

Injection pressure: 70-100 MPa,

The injection molding cycle time is 60 – 180 seconds, including injection time 5 ~ 10 seconds, holding time 5 ~ 15 seconds, and cooling time 20 – 60 seconds.

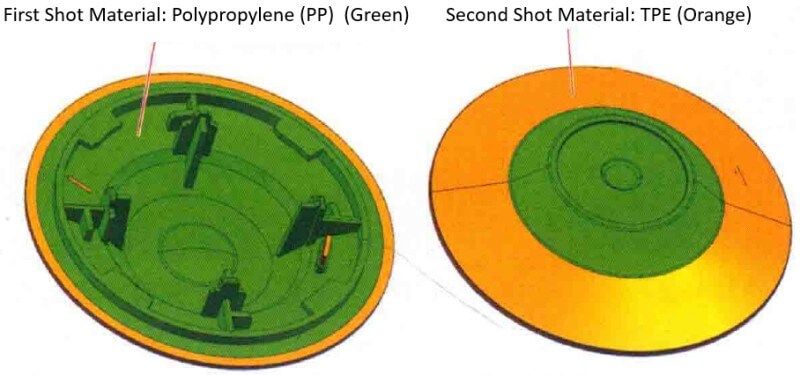

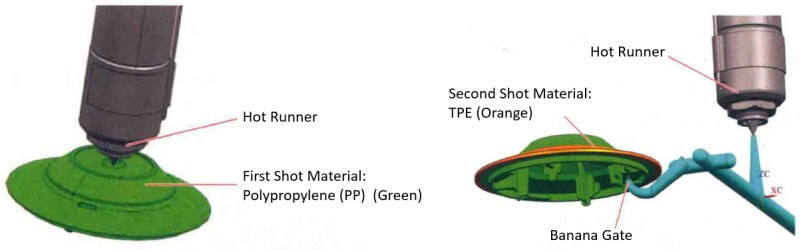

6.1 description of products

This is a 2k injection moulding cast study, the first shot material is Polypropylene (PP), and the second shot material is TPU.

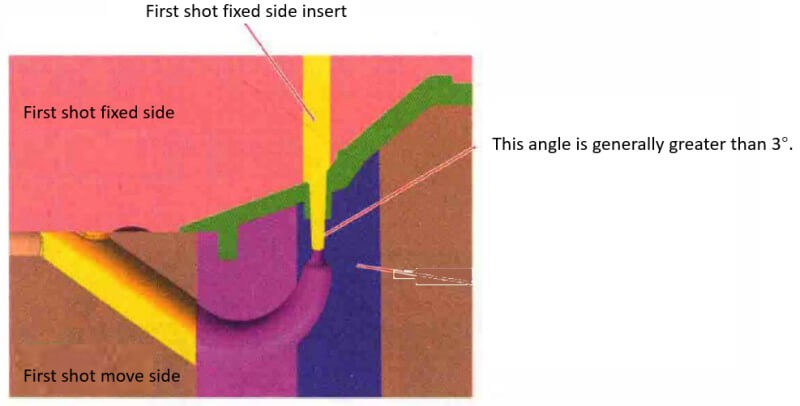

As the below image shows, the green color is the first shot material, Polypropylene (PP), and the orange color is the second shot material, TPU.

Overall dimension: Ø48mm*13.3mm

Cavities: 2+2

6.2 Key points of Injection mold design

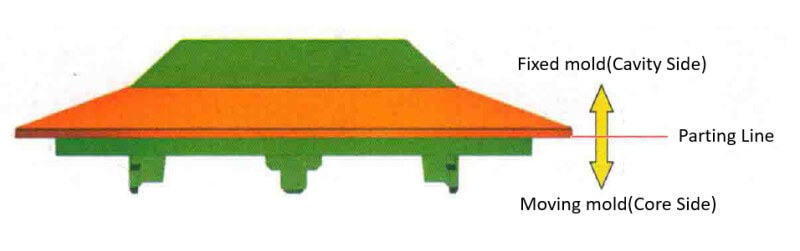

6.2.1 Partling line

In the early stage of mold design, we must first analyze the direction of plastic products and define the parting line.

The parting line of the product is defined as the maximum profile of the product, as shown in the image below. The second shot of the product can be molded in the fixed cavity.

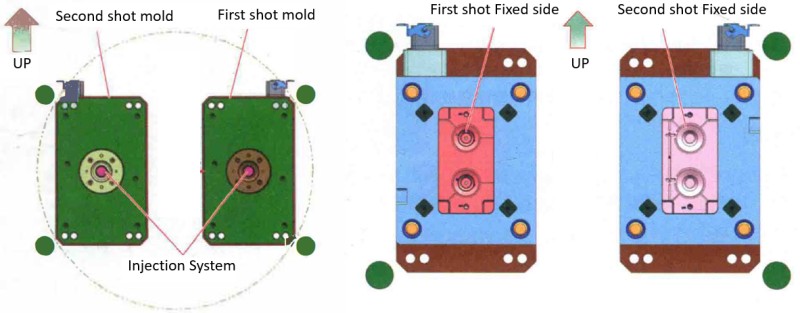

6.2.2 Gate Type And Gate Position

The key point of this case study is how to design the gate type and gate position for the second shot, TPE.

According to the product appearance requirements and considering the production cost, in the first shot, Polypropylene (PP), we design a hot tip at the centre of the product. See the below image.

Since the second shot is cosmetic surfaces, we design a banana gate at the ribs. See the below image.

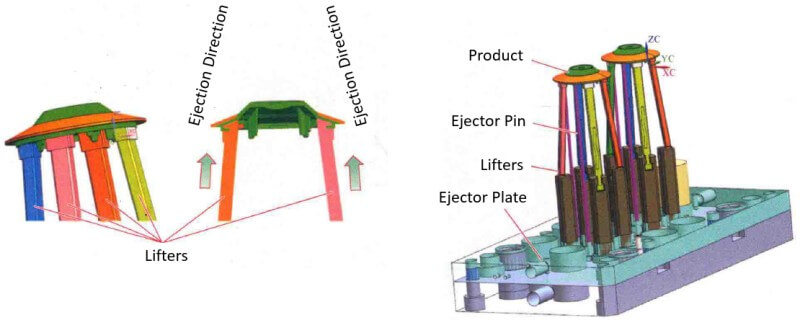

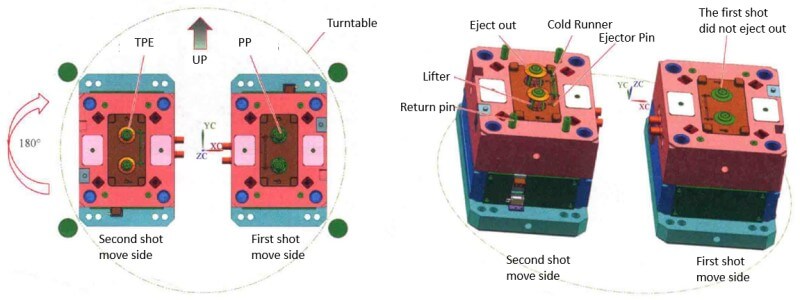

6.2.3 Product Ejection System

The first shot has 4 undercuts at the core side, so we design 4 lifters, and the 4 lifters are enough to eject the first shot out.

After the injection of the first shot, the core side rotated 180°, and then the 4 lifter plus ejector pins to eject the whole product out. See the below image.

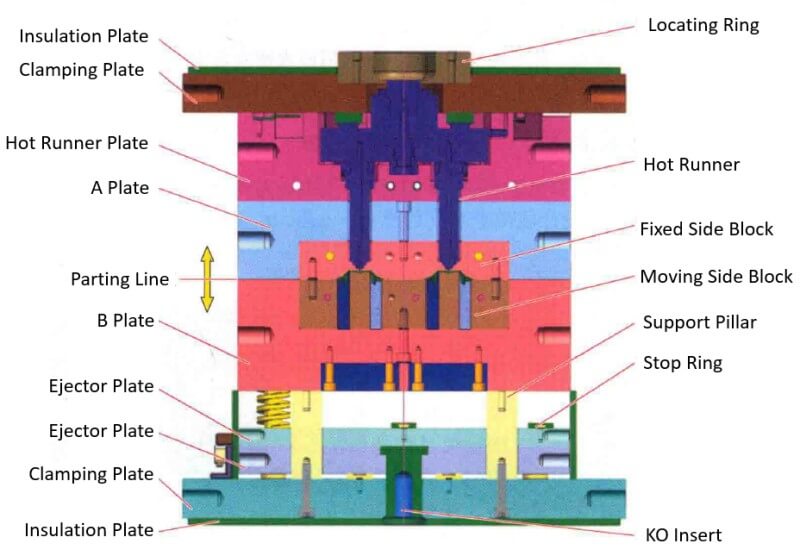

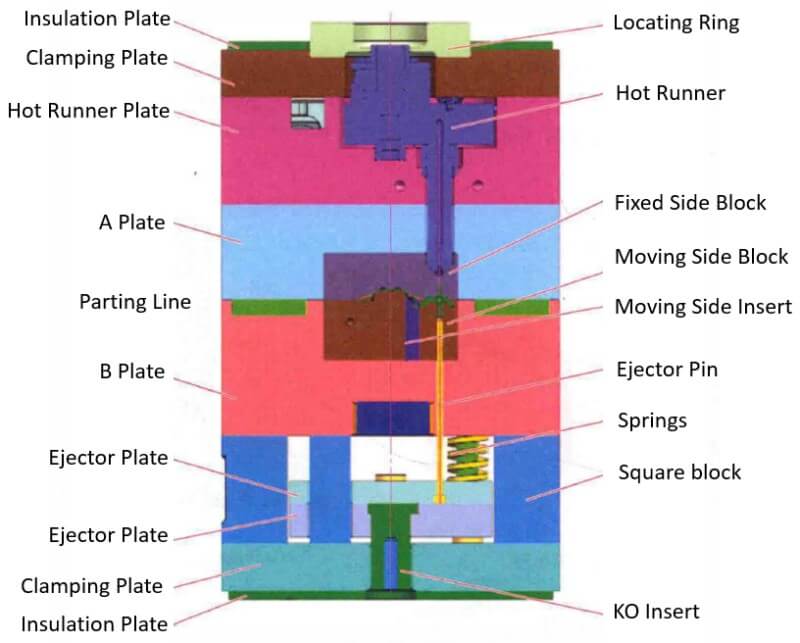

6.3 Main Injection Mold Structure

The following 2 images show the mold structure of the first shot and the second shot respectively.

6.4 Analysis the Polypropylene (PP) Injection Molding Processes

The two-colour injection molding machine of this 2k molds is horizontal parallel injection nozzle, and the distance of the injection nozzle is fixed and cannot be changed.

From the consideration of mold manufacturing cost, this two-color mold is designed as two independent molds, the mold bases are required to be interchangeable, and the mold thickness must be exactly same.

After the mold is installed, the injection molding machine will start the injection molding of the first shot.

After that, the injection molding machine will open the mold and then the turntable of the injection molding machine will rotate 180° and drive the movable mold to rotate 180°, then the injection molding machine will close the mold for the second shot molding.

After that, the injection molding machine will open the mold again, and the product will be ejected by the ejection system of the second shot mold to complete the injection molding of a complete two-color product.

In the actual injection molding production, the first color product and the second color product are molded simultaneously in each injection molding cycle. Two first color products and two complete two-color products are molded together.

After each mold opening, the ejector system of the second color mold drives the ejector plate, ejector pallet, ejector pin and lifters to eject the second color product and cold runner, and then the table of the moving mold rotates to drive the moving mold to the next working position.

The injection molding machine closes the mold and continues the molding process.

6.5 Matters Need Attention

At the gate switch position between the first shot and the second shot, there is a shut-off position between the fixed insert and the moving insert of the first shot, as shown in the image below.

The shut-off angle needs to be designed larger to avoid defects; This angle is generally greater than 3°.